Product Information

Details

GHS Pipe Markers are adhesive backed markers that you peel and stick. Brimar's specially formulated adhesive is applied with a heavy coating to ensure adhesion to a variety of surfaces. Apply markers only to clean and dry surfaces. Minimum of 50°F is required for installation. GHS Pipe Markers comply with ANSI/ASME A13.1 standards if used in conjunction with directional arrows.

Compliance

Additional Means of Identification ASME A13.1

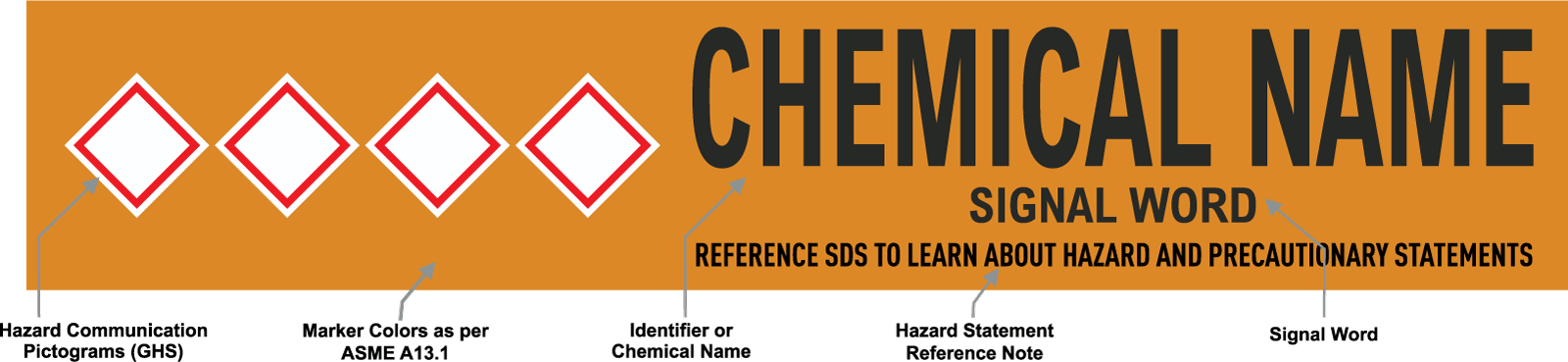

ASME A13.1 incorporated the GHS pictograms into the 2015 revision and has recommended their use as part of the legend.

"The applicable GHS pictograms as illustrated below may be included as part of the legend. Where piping is connected to containers that are labeled in accordance with GHS requirements, a corresponding label on the piping may be provided. The corresponding label should contain at least the product name or identifier, the pictogram, the signal word, and the physical, health, and environmental hazard statements."

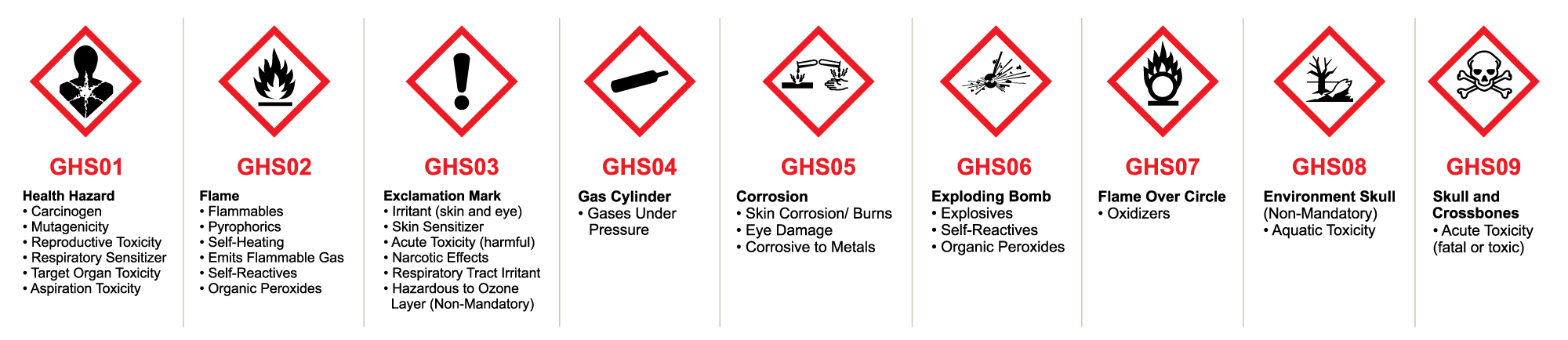

Hazard Communication Pictograms

Nine OSHA approved Hazard Communication pictograms. Each pictogram below is used to alert users of the chemical hazards to which they may be exposed to. The pictogram consists of a black symbol inside a white diamond framed by a red border and each represents a distinct hazard. from no symbols, or up to 6 different symbols can be printed on each marker, depending on the substance you need to identify. The symbol printed on the marker is determined by its chemical hazard classification. Reference to SDS to learn about the hazard classification of each substance you will be exposed to.

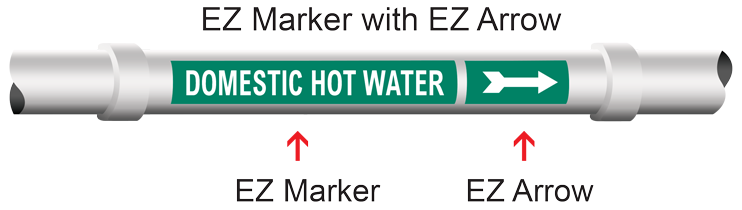

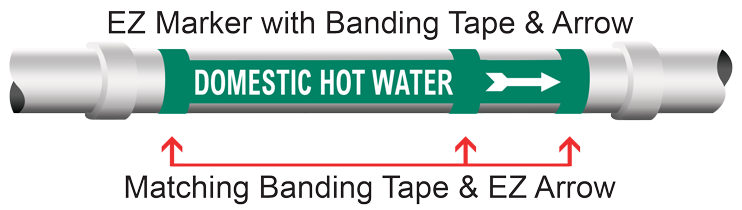

EZ Pipe Markers (Stick On Labels)

Self-adhesive markers you peel and stick

- Brimar's specially formulated adhesive is applied with a heavy coating to ensure adhesion to a variety of surfaces.

- Markers should only be applied to clean and dry surfaces.

- Markers comply with the new ANSI / ASME A13.1 2020 standard if used in conjunction with arrows, all 3 options of assembly shown below are in compliance.

- Durability: 4 to 5 years outdoors

- Service Temp: -20 to 200° F

- Minimum Application Temp: 50° F

- Surface Prep: Clean & Dry

- Spec Compliance: ANSI / ASME A13.1 2020

Size Chart (Pipe Overall Diameter, Marker Size, & Letter height)

The following chart shows the recommended pipe marker letter height and marker size based on the outside pipe diameter, including the insulation of the pipe to be identified. For pipes with an O.D smaller than 3/4″ (19mm) and for valve and fitting identification, the use of a permanent legible tag is recommended.

| Size | 1XSM | 1SM | 1 | 1LG |

|---|---|---|---|---|

| Pide O.D | 3/4" to 1-1/4" |

1-1/2" to 2-3/8" |

2-1/2" to 7-7/8" |

8" to 10" |

| Marker Size (W x H) | 8" x 1-1/2" | 8" x 1-1/2" | 14" x 2-1/4" | 24" x 4" |

| Symbols & Chemical Name |

0.50" | 0.75" | 1.3" | 2.5" |

| Signal Word Size | 3/16" | 3/16" | 1/4" | 1/2" |

Latest Revision ANSI / ASME A13.1

ANSI / ASME is the most common pipe identification standard used in the United States. The standard specifies the primary and secondary means of identifying pipe content, as well as the size, color and placement of the identification device.

1. Primary Identification

The legend (name of pipe content) and directional flow arrow remain the primary means of identifying pipe content. The size and placement of the marker and arrow has not changed. See ANSI / ASME size table and installation recommendations for details.

Legends should use arrows to indicate the direction of flow, where flow can be in both directions, arrows in both directions should be displayed. Contents should be identified by a legend with sufficient additional details such as temperature, pressure, etc. Legends should be brief, informative, pointed, and simple for greatest effectiveness.

2. Secondary Identification

ASME A13.1 4.2 Color: "Color should be used to identify the characteristic hazards of the contents. Color should be displayed on, or contiguous to, the piping by any physical means, but its use shall be used in combination with a legend. Color may be used in continuous, total-length coverage or in intermittent displays. Colors preceded by the word "Safety" shall meet the requirements of ANSI / NEMA Z535.1"

-

FLUID SERVICE COLOR COMBINATIONS Fire Quenching Fluids

Toxic & Corrosive Fluids

Flammable Fluids

Combustible Fluids

Potable, Cooling, Boiler feed, & other Water

Compressed Air

Defined by the User

Defined by the User

Defined by the User

Defined by the User

- Flammable Fluids

- Used for fluids that, under ambient or expected operating conditions, are a vapor or procedure vapors that can be ignited and continue to burn in air. The terms thus may apply, depending on service conditions, to fluids defined for other purposes as flammable or combustible

- Oxidizing Fluids

- Oxidizing fluid is any gas or liquid that may, generally by providing oxygen, cause or contribute to the combustion of other material more than air does.

- Fire Quenching Fluids

- This classification includes water, foam and CO2 used in sprinkler systems and fire fighting piping systems.

- Toxic & Corrosive Fluids

- This classification includes fluids that are corrosive or toxic, or will produce corrosive or toxic substances when released.

- Combustible Fluids

- This classification includes fluids that can burn but are not flammable.

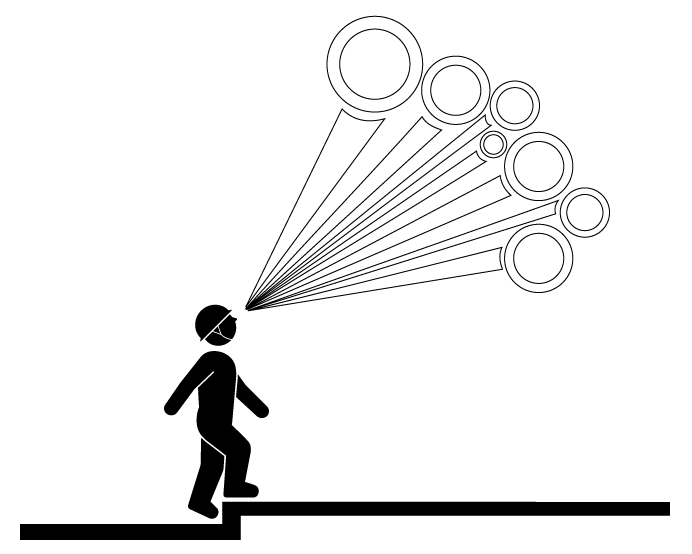

3. Placement

Always position pipe labels on pipes to achieve the best visibility. Install pipe labels below or above the horizontal centerline of the pipe when pipes are located above or below the normal line of vision.

-

Install pipe labels close to valves or flanges.

-

Apply pipe labels adjacent to changes in direction and/or branches.

4. Abandoned Piping

Piping that has been abandoned in place should be identified. The recommended color scheme is a safety white background with black letters. A black border should be added to the identification. When the abandoned piping is protected from corrosion by the addition of a pressurized fluid or contains residual hazardous material, the legend should indicate that.