Custom ANSI Z535.4 & ISO 3864-2 Safety Labels with Stock or Custom Image Option

The label image shown to the right is for preview purposes only. Actual product may appear slightly different.

Need to design a custom sign but don’t see a template you like? Email us directly at sales@safetysign.com.

-

Loading…This page could not be loaded. Please try again or contact customer service for assistance.

Select below any of our compliant headers, these headers are available with or without signal word, the headers without it, allow you to type in the signal word in any language.

Enter below your Label Custom Header. Ideal for multi-lingual headers.

Refer to preview on the side to view finished design. To change text size and alignment use controls below.

Refer to preview on the side to view finished design. To change text size and alignment use controls below.

Select an image from our extensive collection, upload your own, or choose None to leave the image area blank. Uploaded images should be at least 300 DPI or have dimensions of at least 1000 pixels on either side for optimal print quality.

For Best Results: PDF, AI, EPS, PS

Other Supported File Types: BMP, JPG, PNG, PSD, SVG, TIF

Files up to 20 MB are supported.

By uploading your file, you warrant that you own or control its rights.

Choose FilePrevNextPrevNextPrevNextPrevNextPrevNextPrevNextPrevNextPrevNextPrevNextPrevNextPrevNextPrevNextStandard mounting holes are included on each custom sign and are pre-selected below. Options for no mounting holes as well as other mounting hole arrangements are available for a small upcharge. These options carry an additional cost because they require a different production method.

Looking for a proof? Don’t use this comment box — You will get to set your printing options for supported products after adding to cart.

Select below from any of the material options available and look to the right to view the different price breaks for each material selected. Click the info icon to learn more about our materials and their characteristics.

Material Visibility Resistance Outdoor Durability Service Temperature Info N/AN/A5 to 8 Years-40° to 302° FThis option will let you position artwork and text vertically or horizontally on sign.

Custom ANSI / ISO Label with ImagePrices are for your custom sign.

Recommended Accessories

Product Information

2 Mil UL® Recognized White Polyester w/ Clear Overlam

SafetySign.com is always looking for ways to provide customers with better signage options. To provide you with labels that last longer in harsh environments, we manufacture UL® Recognized polyester labels.

These UL® Recognized labels are superior to other labels because they perform better and last longer in tough environments.

| Material | Service Temperature | Lifespan |

|---|---|---|

| UL® Recognized Polyester | -40°F to 302°F | 5-8 years |

| Basic vinyl material | 40°F to 180°F | 3-4 years |

These labels have a service temperature range of -40°F to 302°F and an outdoor durability of 5 to 8 years. They resist extreme heat, chemicals, and abrasion. Most of our selection of machine safety labels meet these standards.

These qualities outperform the basic adhesive vinyl labels produced by some manufacturers. Those labels have a service temperature range of up to 180°F and will only last outside for 3 or 4 years.

Non UL® Recognized labels cannot withstand the same type of chemical or abrasion exposure that a UL® Recognized polyester label can.

By using UL® Recognized polyester labels for your needs, you are ensuring that you will have a label that will last and won’t need to be replaced as often as those from other manufacturers.

Compliance

ANSI Z535.4 PRODUCT SAFETY LABELS

To view and print an Informational PDF click on this link: Product Safety Labels Submittal PDF →

To Learn about the Materials used in the making of this sign, refer to the Tab called "Material Descriptions..."

1. Hazard Classification: Signal Word

The first element to consider when designing or selecting a product safety label is to determine the likelihood and severity of a potential injury if a person does not follow the instructions contained on the safety label or sign.

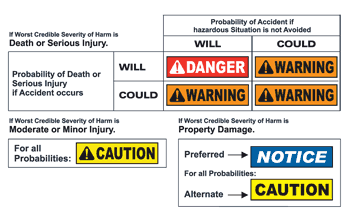

There are four Signal Words or Hazard Classifications used in the design of an ANSI Z535.4 2007 compliant safety label: “DANGER”, “WARNING”, “CAUTION” and “NOTICE”

Click on this link to view: Signal Word Classification

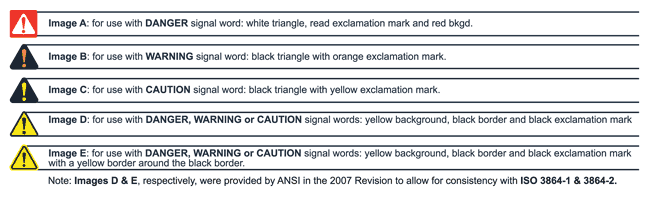

Safety Alert Symbol: Use & Color Definition

ANSI Z535.4 2007 Revision has clarified the Safety Alert Symbol, use and respective colors, it has also incorporated the ISO 3864-1 general warning symbol as an alternate option. See image to learn how to use the safety alert symbol, what colors it should be, and when the use of certain versions (Image D & E) will comply with ISO 3864-2 as well.

Safety Alert Symbol

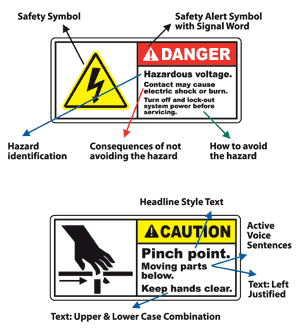

2. Safety Label Format: Message Panel

The message panel of any new ANSI Z535.4 2007 compliant sign or label must contain:

- Identification of the hazard.

- Identification of a means to avoid the hazard.

- Consequences of not avoiding the hazard.

The order in which the information appears in the message panel is flexible and should be determined by logical factors related to avoiding an injury, such as:

- The target audiences knowledge of the hazard.

- And the reaction time to avoid the hazard.

In addition, we recommend, when formatting the message panel, to consider the following practices:

- Use headline style text.

- Use active voice statements.

- Avoid prepositional phrases.

- Use left justification of the text except on one line messages.

- Use upper and lower case letters.

Click on this link to view & print: Brimar's Standard Label Sizes

3. Safety Symbols:

ANSI Z535.4 encourages the use of safety symbols that communicate a comparable message to the worded message on the sign or label. The safety symbol when selected properly, should identify:

- The hazard.

- Identify a means of avoiding the hazard.

- Consequences of not avoiding the hazard.

The safety symbol should clarify or reinforce the worded message on the label. There are four types of safety symbols used on ANSI Z535.4 compliant product safety label. When using safety symbols to comply with ANSI, the symbol can be black on a white background, other colors may be used, like safety red for fire related symbols, and so on.

To comply with both ANSI Z535.4 and ISO 3864, then the following applies, ISO 3864 2002 standards required that all of the safety symbols used on international product safety labels be within a surround shape, yellow equilateral triangle with black inner border for hazard alerting symbols, blue circle for mandatory actions, and red circle with 45° degree slash for prohibition symbols. ANSI Z535.4 2002 does not required the use of a yellow equilateral triangle or the mandatory surround shape but, it does recognize it and permits their use.

Click on this link to view: ANSI Z535 & ISO 3864-2 Safety Symbol Classification

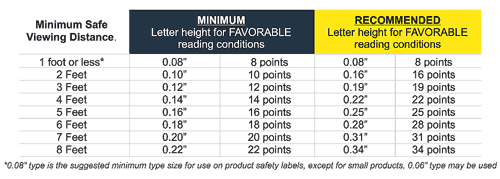

4. Safety Label: Letter Size Legibility

- Lighting.

- Background.

- type font and visual acuity.

Other factors to consider in determining sign size include:

- The complexity of the message, the reaction time necessary and the angle the label will be seen from.

- In many situations it is better to use multiple smaller labels that are strategically positioned than one large label.

Many times letter size may need to be larger than the values shown on the graphic for a variety of reasons:

- To make the sign more noticeable from other information displayed in the area.

- To enable legibility under low light, or other poor viewing conditions.

- To alert persons sooner than the minimum safe viewing distance.

- To convey special importance for portions of the message.

- To improve legibility for persons who have vision problems with small text.

Example of text message letter heights and *minimum safe viewing distances.

* Minimum safe viewing distance refers to the closest distance a person can be to the label and still have time to follow the safety label's message to avoid the hazard.

Click on the link to Open & Print PDF with: Recommended Sign Size & Viewing Distances

5. Safety Labels: Recommended Label Placement

It is well recognized that in many instances, well designed and properly placed safety labels can increase operator and maintenance personnel awareness of the inherent hazards involved when working with machinery.

When installing labels on equipment we recommend to keep in mind the following criteria:

- Label needs to be readily visible to the target audience (personnel that will be in contact with the hazard)

- Label needs to alert the viewer to the hazard in time to take appropriate action.

- Labels are required to be applied on or adjacent to the area where the hazard is present.

- Labels are required to be permanently affixed to the equipment.

- Ensure the surface to which the label(s) will be applied on is clean and free of dirt, dust, grease and moisture. If the surface is painted, paint must be dry.

- Press the label on after applying it to the surface. One or more passes over with a rag or roller will ensure that the label is completely glued on the surface and will not fall off.