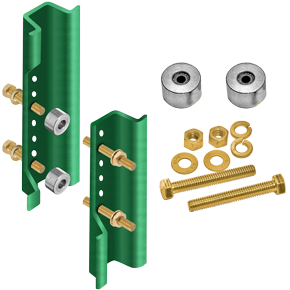

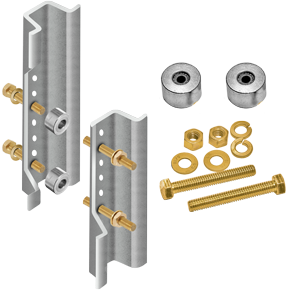

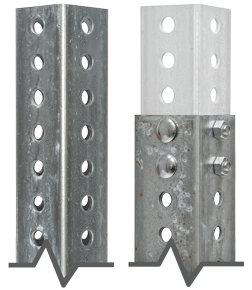

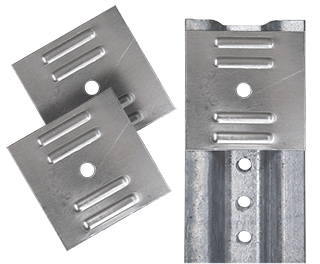

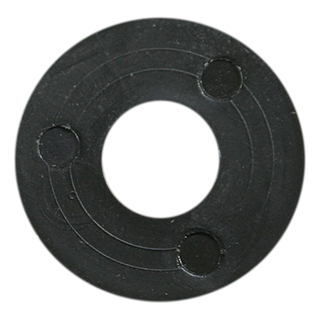

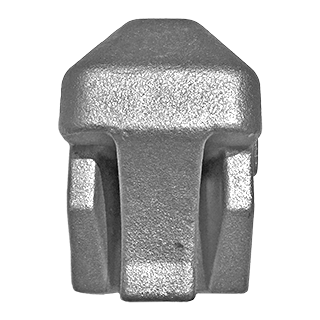

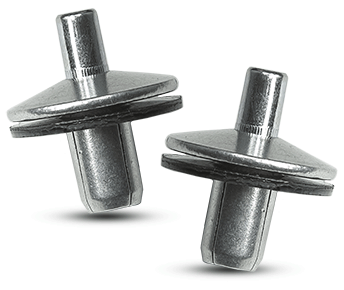

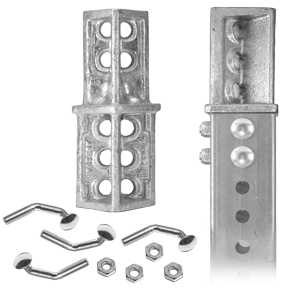

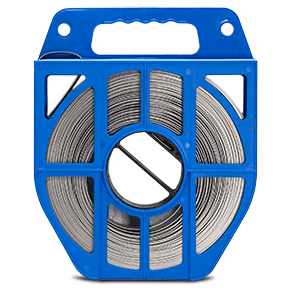

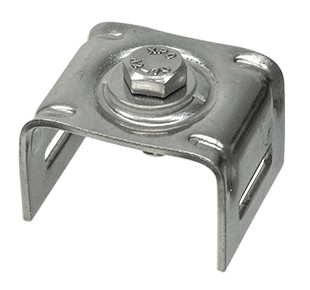

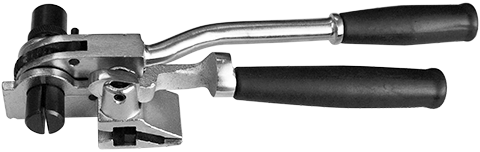

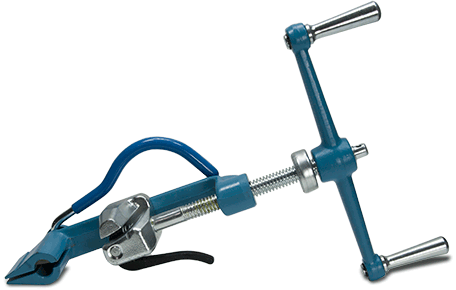

Recommended Accessories

Product Information

Details

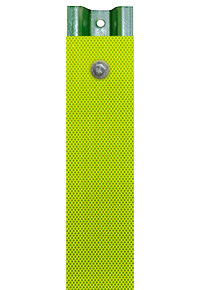

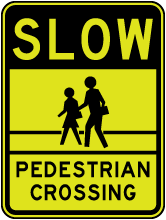

This Ahead Sign has effective messages or images for traffic and pedestrian safety concerns. An Ahead Sign is a helpful resource to aid in the protection of the health and safety on roads, and is not an alternative for required protective measures for eliminating or reducing hazards.

Other available signs: