Product Information

Details

High Temp. Oxygen High Temp. Wrap Around & Strap On Pipe Marker are used to identify piping systems in industrial environments that are expected to reach higher temperatures or harsh exposure to chemicals. High Temp. Wrap Around & Strap On Pipe Markers meet specification compliances for ANSI / ASME A13.1 standards for the identification of pipes. No pipe preparation is needed for these markers. Oxygen High Temp. Wrap Around & Strap On Pipe Marker are available in wrap-around and strap-on formats for pipe outside diameters ranging from 1/2 inch to over ten inches and provide 360 degree visibility.

Compliance

System #4 Pipe Markers™ (High Temp Markers)

These markers are designed to withstand harsh chemicals, abrasion, and weather all environments. The printed legend is laminated between two layers of polyester, creating an extremely DURABLE product.

- UV Printed legend is laminated between two layers of polyester, creating an extremely DURABLE product.

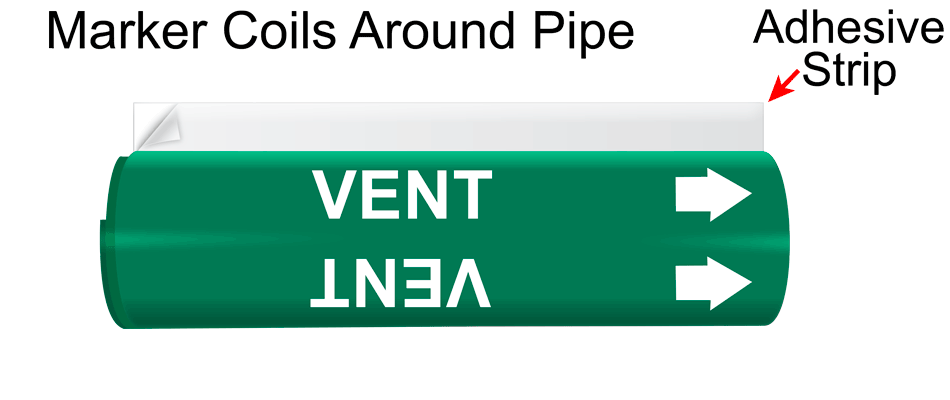

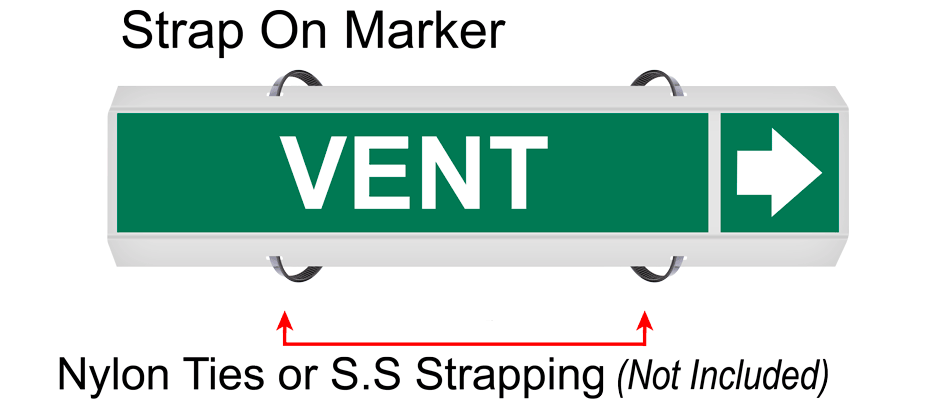

- These Markers are available in 2 ways, markers that Wrap Around pipe and markers that are laminated to Black Carrier (Strap On).

- For pipe diameters 1/2" thru 7-7/8" use Wrap Markers (Styles 4A, 4B, 4E, 4F) these markers will wrap around pipe and are secured in place by an overlapping clear adhesive strip.

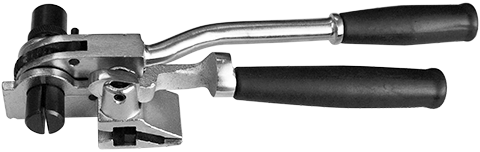

- For pipe diameters 8" or larger use Strap On Markers (Styles 4G & 4H) these markers are laminated to a heat and chemical resistant carrier that is then strapped on to pipe with nylon ties or stainless steel strapping.

- Durability: 5 to 8 years outdoors

- Service Temp: -40° to 248° F

- Minimum Application Temp: None

- Spec Compliance: ANSI / ASME A13.1 2015

Marker Size, Letter Height & Max. Characters Per Marker Chart

The following chart shows the recommended pipe marker letter height and marker size based on the outside pipe diameter of the pipe to be identified. For pipes smaller than 3/4" and for valve identification, the use of a permanent legible tag is recommended.

| Size | 4A | 4B | 4E | 4F | 4G | 4H |

|---|---|---|---|---|---|---|

| Pipe O.D | 1/2" to 1" | 1-1/8" to 2-3/8" |

2-1/2" to 4-3/4" |

5" to 7-7/8" |

8" to 10" | Over 10" |

| Marker Length | 8" | 8" | 12" | 12" | 24" | 32" |

| Letter Size | 0.50" | 0.75" | 1.3" | 1.3" | 2.5" | 3.5" |

| Max Characters | 22 | 18 | 22 | 22 | 22 | 16 |

Brimar's Wrap Around & Strap-On System #4 Pipe Markers

-

STYLE 4A (Wrap Around)

Pipe O.D 1/2" to 1"

Legend Size: 1/2" High

Marker Size: 8" wide -

STYLE 4B (Wrap Around)

Pipe O.D 1-1/8" to 2-3/8"

Legend Size: 3/4" High

Marker Size: 8" wide

-

STYLE 4E (Wrap Around)

Pipe O.D 2-1/2" to 4-3/4"

Legend Size: 1-1/4" high

Marker Size: 12" wide -

STYLE 4F (Wrap Around)

Pipe O.D 5" to 7-7/8"

Legend Size: 1-1/4" high

Marker Size: 12" wide

-

STYLE 4G (Strap On)

Pipe O.D 8" to 10"

Legend Size: 2-1/2" high

Marker Size: 24" wide -

STYLE 4H (Strap On)

Pipe O.D. Over 10"

Legend Size: 3-1/2" High

Marker Size: 32" wide

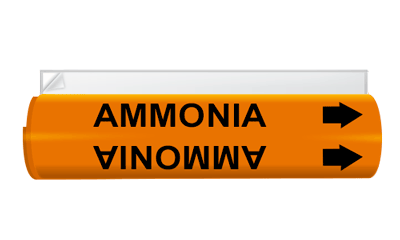

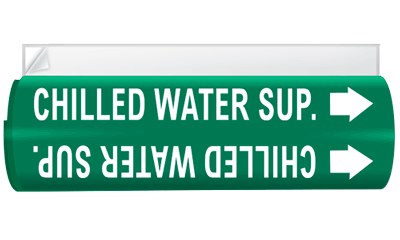

Colors:

The secondary means of identification is the color code of the marker. The exact colors are contained in the ANSI Z535.1 Safety Color Code. Color is the secondary means to identification but many times the most important. The color of the marker should be used to identify the characteristic hazard of the contents of the pipe. The following chart list the classifications shown by ANSI / ASME A13.1 2015 as the suggested color combinations for the pipe markers.

-

FLUID SERVICE COLOR COMBINATIONS Fire Quenching Fluids

Toxic & Corrosive Fluids

Flammable Fluids

Combustible Fluids

Potable, Cooling, Boiler feed, & other Water

Compressed Air

Defined by the User

Defined by the User

Defined by the User

Defined by the User

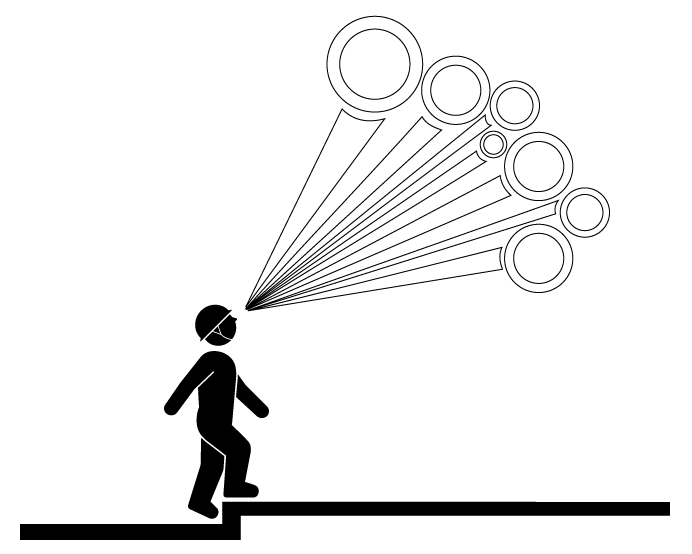

3. Placement

Always position pipe labels on pipes to achieve the best visibility. Install pipe labels below or above the horizontal centerline of the pipe when pipes are located above or below the normal line of vision.

-

Install pipe labels close to valves or flanges.

-

Apply pipe labels adjacent to changes in direction and/or branches.