- Item #

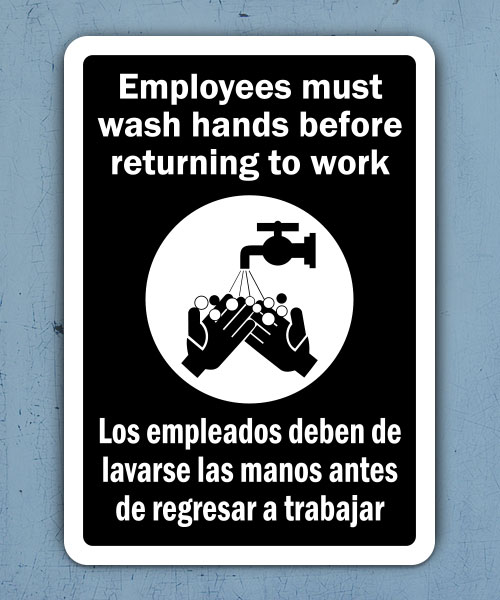

- D5826-AB

- Label Reads

-

Employees Must Wash Hands Before Returning To Work / Los Empleados Denben De Lavarse Las Manos Antes De Regresar A Trabajar

- Language

- Bilingual (English/Spanish). Also available in English.

- Compliance

-

- LEED Compliant

- ECCN Certification

Other configurations of this product are RoHS Compliant, UL® Recognized, California Proposition 65, and REACH SVHC.