- Item #

- J6641-SFB

- Compliance

-

- ANSI Z535 / OSHA

- CEMA

- LEED Compliant

- RoHS Compliant

- UL® Recognized

- California Proposition 65

- ECCN Certification

- REACH SVHC

Recommended Accessories

Product Information

Details

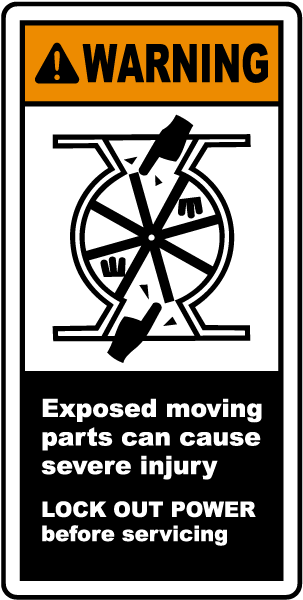

An Exposed Moving Parts Lock Out Label has official ANSI headers for safety protocol and compliance. An Exposed Moving Parts Lock Out Label is a helpful resource to help protect the health and safety of personnel, and is not a substitute for required protective measures for reducing or eliminating hazards.

Compliance

Conveyor Safety Labels (Compliance with ANSI Z535.4 & CEMA)

What does OSHA say about Identifying Conveyor Hazards?

Cranes, Derricks, Hoists, Elevators, and Conveyors - §1926.555

- Means for stopping the motor or engine shall be provided at the operator's station. Conveyor systems shall be equipped with an audible warning signal to be sounded immediately before starting up the conveyor.

- If the operator's station is at a remote point, similar provisions for stopping the motor or engine shall be provided at the motor or engine location.

- Emergency stop switches shall be arranged so that the conveyor cannot be started again until the actuating stop switch has been reset to running or "on" position.

- Screw conveyors shall be guarded to prevent employee contact with turning flights.

- Where a conveyor passes over work areas, aisles, or thoroughfares, suitable guards shall be provided to protect employees required to work below the conveyors.

- All crossovers, aisles, and passageways shall be conspicuously marked by suitable signs, as required by Subpart G, Signs, Signals, and Barricades.

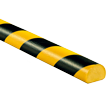

- Conveyors shall be locked out or otherwise rendered inoperable, and tagged out with a "Do Not Operate" tag during repairs and when operation is hazardous to employees performing maintenance work.

- All conveyors in use shall meet the applicable requirements for design, construction, inspection, testing, maintenance, and operation, as prescribed in the ANSI B20.1-1957, Safety Code for Conveyors, Cableways, and Related Equipment.

What has CEMA done about Identifying Conveyor Hazards?

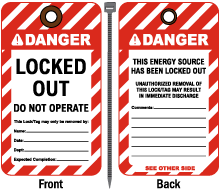

CEMA has developed Industry a Standard Safety Labels, CEMA Brochure 201 - "Safety Label Brochure". These labels are broken down into Danger, Warning, and Caution Safety Labels, the purpose of the labels is to identify common and uncommon hazards, conditions, and unsafe practices which can injure, or cause the death of, the person(s) who is working at or around the conveying equipment. The labels by themselves cannot prevent unsafe acts. The label and placement program is intended as a voluntary guide and should be incorporated into a comprehensive safety program by users of conveyors and related equipment as part of their effort to prevent injuries.

As stated on CEMA’s website: “CEMA Safety Labels and Placement Guidelines were developed by the CEMA Safety Committee to provide for members and non-members consensus advice for the selection and application of safety labels for use on conveyors and related material handling equipment to assist in accident prevention.”

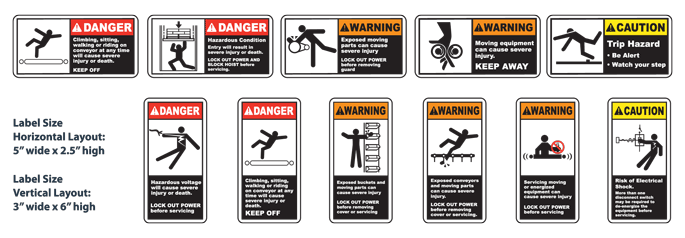

Examples of CEMA Safety Labels sold on SafetySign.com

CEMA's Logic in Support of English Language Labels on OEM Equipment Destined for the U.S. Marketplace

The CEMA Safety Labels were designed as Manufacturers' Warnings to the users of their equipment. The Standard CEMA Safety Label has three components:

- The Alert (Danger, Warning or Caution)

- The Pictogram (a nonverbal depiction of the conduct to be avoided)

- The Message (words to enhance the message depicted by the Alert and Pictogram)

All CEMA Messages are in English, and for a good reason. The Alert and The Pictogram are deemed by ANSI to be sufficient to alert a purchaser and user that some hazard exists near the equipment. It is the user’s responsibility to explain and expand on the hazards that are depicted by the Safety Label, as well as other problems which may be encountered while operating the equipment, by virtue of its installation, but which might not be labeled.

To learn more about CEMA and CEMA’s Safety Labels click this link to view CEMA’s Conveyor Safety Page

Safety Symbols:

ANSI Z535.4 2002 encourages the use of safety symbols that communicate a comparable message to the worded message on the sign or label. The safety symbol when selected properly, should identify:

- The hazard.

- Identify a means of avoiding the hazard.

- Or identify the consequences of not avoiding the hazard.

The safety symbol should clarify or reinforce the worded message on the label. There are four types of safety symbols used on ANSI Z535.4 2002 compliant product safety labels. When using safety symbols to comply with ANSI, the symbol can be black on a white background, other colors may be used, like safety red for fire related symbols, and so on.

To comply with both ANSI Z535.4 and ISO 3864, then the following applies, ISO 3864 2002 standards required that all of the safety symbols used on international product safety labels be within a surround shape, yellow equilateral triangle with black inner border for hazard alerting symbols, blue circle for mandatory actions, and red circle with 45° degree slash for prohibition symbols. ANSI Z535.4 2002 does not require the use of a yellow equilateral triangle or the mandatory surround shape but, it does recognize it and permits its use.

Click on this link to view ANSI Z535 & ISO 3864-2 Safety Symbol Classification Click on this link to view Conveyor Safety Symbols Database

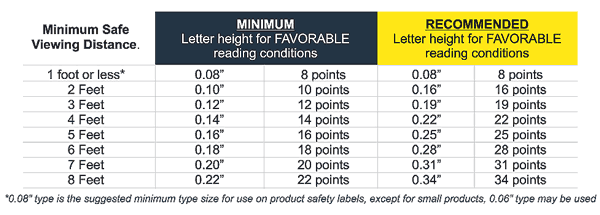

Safety Label: Letter Size Legibility

Determining the safe viewing distance of a sign depends upon many factors:

- lighting

- background

- type font and visual acuity.

Other factors to consider in determining sign size include:

- the complexity of the message, the reaction time necessary and the angle the sign will be seen from.

- In many situations it is better to use multiple smaller signs that are strategically positioned than one large sign.

Many times letter size may need to be larger than the values shown on the graphic for a variety of reasons:

- To make the sign more noticeable from other information displayed in the area.

- To enable legibility under low light, or other poor viewing conditions.

- To alert people sooner than the minimum safe viewing distance.

- To convey special importance for portions of the message.

- To improve legibility for people who have vision problems with small text.

Example of text message letter heights and *minimum safe viewing distances.

* Minimum safe viewing distance refers to the closest distance a person can be to the label and still have time to follow the safety label's message to avoid the hazard.

Safety Labels: Recommended Label Placement

It is well recognized that in many instances, well designed and properly placed safety labels can increase operator and maintenance personnel awareness of the inherent hazards involved when working with machinery.

When installing labels on equipment we recommend to keep in mind the following criteria:

- Label needs to be readily visible to the target audience (personnel that will be in contact with the hazard)

- Label needs to alert the viewer to the hazard in time to take appropriate action.

- Labels are required to be applied on or adjacent to the area where the hazard is present.

- Labels are required to be permanently affixed to the equipment.

- Ensure that the surface to which the label(s) will be applied on is clean and free of dirt, dust, grease and moisture. If the surface is painted, ensure that the paint is dry.

- Press the label on after applying it to the surface. One or more passes over with a rag or roller will ensure that the label is completely glued on the surface and will not fall off.