- Item #

- H1665-BO

- Compliance

- OSHA 1910.1200(c)

Other configurations of this product are LEED Compliant and ECCN Certification.

Recommended Accessories

Product Information

Details

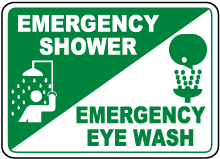

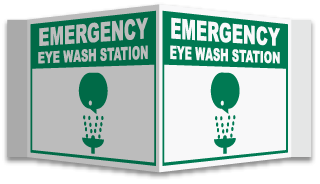

This MSDS Station Sign uses safety text and/or images for chemical safety protocol and compliance. A MSDS Station Sign is a useful tool to help protect the health and safety of personnel, but is not a substitute for required protective measures for eliminating or reducing hazards.

Other available signs:

About InfiniStick™ Labels

We engineered our InfiniStick™ labels for maximum adhesiveness and durability. InfiniStick™ labels are made with Brimar’s specially formulated adhesive and ultra-durable vinyl and can withstand the most challenging conditions without peeling off. Safe for use between -20° to 176° F and capable of sticking to a wide range of smooth and rough surfaces, InfiniStick™ labels are ideal for nearly any application.

InfiniStick™ labels adhere to a wide range of surfaces, making them perfect for use outdoors, in industrial settings, on machines, containers, vehicles, and more. For maximum adhesion, simply wipe the surface clean, remove the film from the label, and stick.

Thanks to their durability and versatility, InfiniStick™ labels will remain in place and effective for years, saving you money compared to standard labels, which must be replaced more frequently. Whether your label contains a safety warning, hazard rating, or any other directive, you can count on the resilience of labels made with InfiniStick™ technology.

Compliance

OSHA MSDS updated to SDS

In 2012, OSHA made big changes to its Hazard Communication Standard (HCS) (29 CFR 1910.1200(g)), aligning it with the United Nations' global chemical labeling system. These changes help to protect workers who handle hazardous chemicals by improving the ways in which those hazards are communicated.

One of the changes OSHA made in the revised Hazard Communication Standard, referred to as HazCom 2012, was with the format of the Safety Data Sheets or SDS. Under the old HazCom 1994, an MSDS could have a number of different formats. The most common safety data sheets were the 8 section OSHA MSDS and the 16 section ANSI MSDS. With the adoption of GHS in the HazCom 2012 however, material safety data sheets are to feature a strict ordering of 16 sections and will now be referred to as simply Safety Data Sheets or SDS.

- The 16 sections are as follows

- Section 1: Identification

- Section 2: Hazard(s) Identification

- Section 3: Composition/Information on Ingredients

- Section 4: First-Aid Measures

- Section 5: Fire-Fighting Measures

- Section 6: Accidental Release Measures

- Section 7: Handling and Storage

- Section 8: Exposure Controls/Personal Protection

- Section 9: Physical and Chemical Properties

- Section 10: Stability and Reactivity

- Section 11: Toxicological Information

- Section 12: Ecological Information (non-mandatory)

- Section 13: Disposal Considerations (non-mandatory)

- Section 14: Transport Information (non-mandatory)

- Section 15: Regulatory Information (non-mandatory)

- Section 16: Other Information

Click here to see a detailed summary from OSHA of the information an SDS needs to contain.

The following are key OSHA standards regarding Safety Data Sheets:

- 1910.1200(g)(8)

- The employer shall maintain in the workplace copies of the required safety data sheets for each hazardous chemical, and shall ensure that they are readily accessible during each work shift to employees when they are in their work area(s). (Electronic access and other alternatives to maintaining paper copies of the safety data sheets are permitted as long as no barriers to immediate employee access in each workplace are created by such options.)

- 1910.1200(g)(9)

- Where employees must travel between workplaces during a work shift, i.e., their work is carried out at more than one geographical location, the material safety data sheets may be kept at the primary workplace facility. In this situation, the employer shall ensure that employees can immediately obtain the required information in an emergency.

- 1910.1200(g)(10)

- Safety data sheets may be kept in any form, including operating procedures, and may be designed to cover groups of hazardous chemicals in a work area where it may be more appropriate to address the hazards of a process rather than individual hazardous chemicals. However, the employer shall ensure that in all cases the required information is provided for each hazardous chemical, and is readily accessible during each work shift to employees when they are in their work area(s).

- 1910.1200(g)(11)

- Safety data sheets shall also be made readily available, upon request, to designated representatives, the Assistant Secretary, and the Director, in accordance with the requirements of § 1910.1020(e).

For the complete OSHA standard and more information on hazard communication Click here.

SafetySign.com does not recommend or specify the use of a specific safety sign because it does not have knowledge of the hazard(s) our customers are identifying. It is the customer’s sole responsibility to identify the hazard(s) that may be present and select one or more signs (stock or custom) that accurately identify their specific hazard(s) and complies with any applicable federal, state or local laws or regulations, any worksite specific rules or regulations and/or any applicable safety standards (including, without limitation, ANSI and/or OSHA standards). SafetySign.com disclaims any and all liability (excluding liability for our Product Warranty contained in our Terms and Conditions) for any sign selected by a customer and shall not be responsible for any personal injury or property damage resulting from the use of signs purchased from it or for the independent interpretation made of any applicable federal, state or local laws or regulations, any worksite specific rules or regulations, and/or any applicable safety standards (including, without limitation, ANSI and/or OSHA standards). Customer shall indemnify and hold SafetySign.com and its corporate parent and its officers, directors and affiliates harmless from and against any and all claims, loss or expense (including attorneys’ fees) arising from or related to the purchase and use by customer or any third party of any sign purchased by customer from SafetySign.com.